Newsletter - March 2016

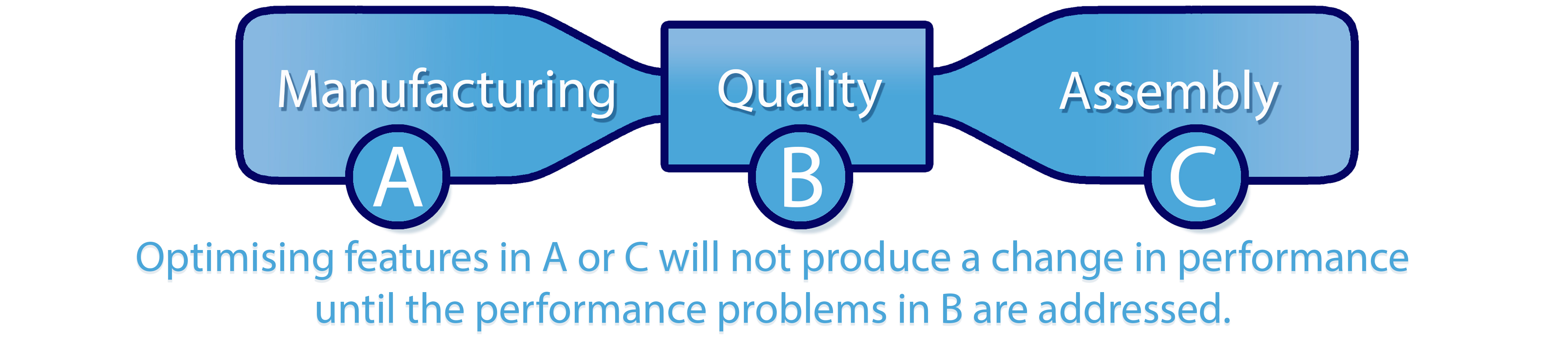

Is it usual for your company to complete the CNC programming, machine parts, then have them sit in inspection waiting for the CMM program to be completed.

Free up your valuable resources and alleviate workload ‘bottle necks’ by having programs ready to run in advance of production machining.

CMM Programming

Onsite Programming

Our engineers can generate programs at your facility using your CMM. The method in which the programs are constructed is entirely your choice and any combination below can be selected

- Create a CMM Program directly from a drawing

- Create a CMM Program using a CAD model and any associated PMI data

- Create a CMM Program using a combination of the above

Offsite Programming

Programming can be completed offsite without utilising your CMM capacity. The method in which the programs are constructed is entirely your choice and any combination below can be selected

- Send us a Part and drawing and we will create the program on our CMM

- Send us a CAD model and we will create the CMM program offline

- Create a CMM Program using a combination of the above

Why choose the off site method?

- Program generation will not impact on your CMM capacity

- Create a program from CAD even if you do not have a physical part

- Eliminate inspection waiting time by having the CMM program ready to go

To find out more about off site programming please contact us by clicking here.

Generic Parts

Are your parts generic in shape but of different sizes?

Focus Inspection can construct a program that can be used to measure a number of parts in the same family simply by altering a data file containing the dimensions for each part.

This method of programming allows you to add new part programs of the same family type to your CMM at a later date as new designs are presented to your company for manufacture.

To find out if generic programming is right for your company please contact us by clicking here.Bespoke Programming

If your requirement is more specific for example

- Do you require a specific type of output?

- Is your customer demanding the results are to be formatted into their form?

- Do you need to transfer data to another software package?

- Do you require a simpler front end interface for operators to use?

Focus Inspection has undertaken many of these tasks and may already have routines that can help you achieve your goal. If we do not have a routine available then we can program a solution that can be tailored to your requirements.

If you are interested in our bespoke programming please contact us by clicking here.Translation of exisiting programs

For some companies upgrading there CMM software to a modern product can be daunting because they have so many existing CMM programs. Focus Inspection can provide a translation service to convert your legacy programs so that they may be run on current software.

To find out more about this service please contact us by clicking here.Our Engineers

Focus Inspection has highly skilled and qualified engineers supporting all major CMM software products. We provide a creditable alternative to your OEM. Our engineers have experience of working in the following industry types

- Ministry of Defence

- Aerospace

- Pharmaceutical

- Automotive industry

Benefits of CMM Programs

Automating measurements using programs for your CMM provides a wealth of benefits:

- Part measurement consistency and repeatability

- Enhanced traceability

- Streamlined processes

- Improved productivity

- Reduced manufacturing costs

Demonstration & Training

Focus Inspection

Foxley E, Kington Park

Malmsbury Raod

Kington st Michael

Chippenham

Wiltshire

SN15 5PZ